#Angular position sensors

Explore tagged Tumblr posts

Text

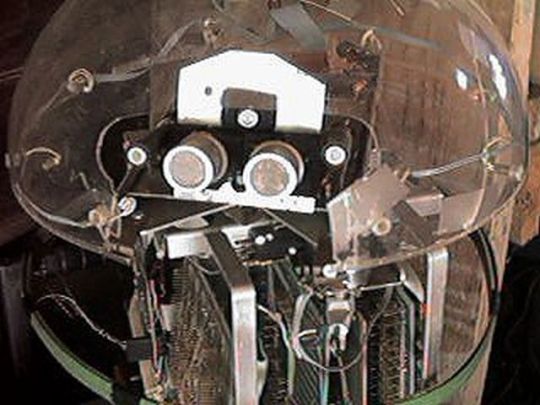

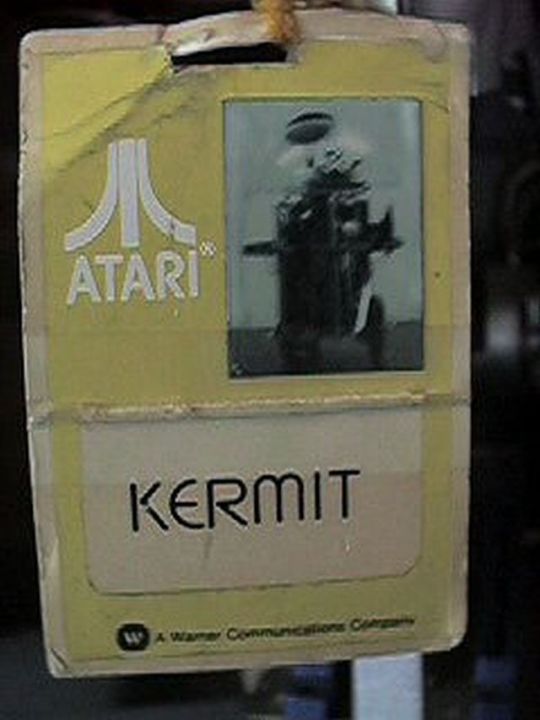

Kermit (1978), by Ron Milner and Larry Nicolson, Cyan Engineering, Atari's secret think tank in Grass Valley, CA.

"The robot was a pet project for Nolan Bushnell, then still the head of Atari and a very creative guy. Its purpose in life was as Nolan put it to "bring me a beer!" Navigation for robots was a sketchy thing at that time with lots of pioneering work at MIT but no consumer cost ideas. Nolan brought us the incredibly original idea to navigate a robot (which mostly meant knowing where it was) by means of scanning bar codes attached here and there to the baseboards in the rooms the robot was to service. Why it wasn't patented I don't know.

I had lots of fun building the R2D2 style robot about 20" tall. I liked to put mechanical and electronic things together and we had a great shop at Cyan. Its brain was one of the 6502 based single board computers-I think it was a KIM but not sure. Locomotion was two DC gear motor driven wheels and an instrumented caster-about the same rig as a modern Roomba. A rotatable turret covered with a plexiglass dome carried microphones, an IR sensor to detect people, and ultrasonic ranging sensors I built on a separate PC board. A speaker so Kermit could beep gleefully, of course.

A ring of contact-detecting burglar alarm sensing tape (green in the pictures) around Kermit's middle told the software he had hit something and should back off. The ultrasonics provided range to obstacles and to some extent direction as the turret was rotated, so we could go around things.

My pride and joy was the barcode remote scanner which was mounted on the bottom of the robot so its rotating head would be level with the barcodes on the baseboards. It had a vertical telescope tube with a beam splitter between the IR Led and the photodiode sensor and a lens to focus 2-20' away. It aimed down at a front surface mirror at 45 degree to scan horizontally. The mirror was mounted on a motor driven turret so it spun around continuously with a sensor once around to resolve the continuous angular position of the beam horizontally of course with respect to Kermit's rotational position. Unfortunately, this part of the robot did not survive the closing of our group. The barcodes I made for the prototype to detect were about 4" tall made of 3/4" reflective 3m tape on black poster board.

My programming partner on the project was Larry Nicholson, a really bright guy. He made the barcode reading work to detect not only the barcodes, but where they were angularly with respect to the robot and also their subtended angle or apparent size (all from timing of the rotation of the scanner) which was a measure of distance combined with angle from the barcode. We worked out some pretty clever math to resolve that information from two or three of the barcodes into a position and orientation of Kermit in the room. We had rented an empty room upstairs on the third floor of the Litton building to try all this out and work out the navigation. Larry and I got the basic navigation and obstacle avoidance working so Kermit could go from one place to a designated other place in the room and avoid wastebaskets placed randomly. We demonstrated it to Nolan and he was impressed.

Shortly thereafter Warner Communication who had bought Atari from Nolan kicked him out and the Kermit project was cancelled."

– Kermit The Robot Notes by Ron Milner.

65 notes

·

View notes

Note

A combat subaltern strides across the hangar deck, one arm tucked behind its back, the other positioned near the bullpup laser carbine mag-clamped to its thigh. Its armored silhouette is sleek and biomimetic: digitigrade legs supported by bundles of synthmuscle, an oblong torso sloped to deflect kinetics, and a distinctly inhuman head, its face dominated by eight optical sensors arranged in double staggered rows.

An SSC design, almost surely.

Like a bodyguard, the subaltern escorts a second, smaller figure. A hologram projected from a shoulder-mounted emitter: the image of a coyote with a light tan coat.

The pair approach hangar 3B, where the vessel Stormpierce is docked, and make their way to the nearest members of the Company. When the coyote addresses them, its voice issues from speakers on the subaltern, producing a disconcerting effect.

“Well, good to see you. I am Ma’ii, of Luna Wing. This is the Black Torrent Mercenary Company, I gather? You have quite a ship here.”

[The ship is an angular thing, made of sloped panels of armor, reinforced and tempered for a variety of battles or situations. The name 'Stormpierce' is emblazoned on the side in black, against the deep cobalt blue of the plating. It's designed for speed and maneuverability most likely, though the ship itself has plenty of spacing for hidden armaments. It's a large ship despite this, needing to be able to house each mech of the mercenary company, in addition to any other necessities.]

[A woman can be seen standing at the base of the ship, talking with a station crew member. Her hair is a pale blonde, matched by her equally as pale skin. Silvery scars can be seen across what little of her skin is visible, the most notable two on her face. She's still in her hardsuit, which is of a matching theme to the ship itself. It's clearly built to allow for flexibility and quick movements, while still being protective from a majority of hits.]

[As the subaltern and hologram duo approaches, she turns, giving a nod. Her gaze is steely, matched by the oddly warm ocean blue of her eyes. She stands in what is obviously a more.. militant at ease pose, which certainly fits how she acts on the omninet.]

<Flashflood> "Ma'ii, I presume? I am Silvania, but please, call me Silvia. To answer your question, yes, you have arrived at the ship for Black Torrent Mercenary Company. It is good to meet you in person."

<Flashflood> "The others I believe are off on business, taking some time to gather more personal items from the station's various shops.. Though, I do believe Ambrosia should be around here. She'll introduce herself when the time comes, I suppose," [Silvania continues, glancing around to look for the enigmatic pyromaniac.]

[A moment later, a subaltern exits from a small boarding ramp of the ship. They are rather distinct; deep grey armor, edged in silver and deep cobalt heraldry to match the colors of the ship itself. It appears as if they are in full plate, the armor having a distinctly draconic theme to it, with the helmet appearing closer to the head of a dragon from old-Cradle myths.]

<Tempestas> "Callsign Ambrosia, otherwise known as Alaine, is currently predisposed with attempting to mix pure ethanol with reactor coolant. Frankly, I am surprised she is still alive." [He responds, filling in for Silvania as he approaches. His voice is a calm baritone, reminiscent of a perfectly still lake. The two are surprisingly alike in how they present themselves.]

#lancer rpg#oc rp#lancer rp#black torrent mercenary company#oc rp blog#lancer oc#The meeting begins!

27 notes

·

View notes

Text

Eterna lore: races pt 1

okay i said i was gonna do it and i'm nothing if not a goblin of my word. here's the breakdown on the races and social hierarchy on the planet Eterna! starting from the top

(note: each race has inherent powers, but all races tend to have some grasp on general magic)

The Rune

Position: The Rune are the gods of this world. Except, unlike gods on Earth, these fellas are super hands-on. They created the races and they rule over Eterna. Nothing happens without their approval. Despite their prominent roles in the lives of Eternals, however, the Rune are hardly ever actually seen. They're kind of like those real historical figures that balloon into legends, except they also control the government.

Physical appearance: The Rune are a bit eery. They're weirdly smooth, splotched with stark white and black, and they have very few discernible facial features. Their eyes are more like clusters of sensors and they have huge, deer-like antlers. Their bodies more or less resemble flowing sheer robes.

Powers: The limits of their powers aren't well-known, but it's generally assumed that they're all-powerful. Still, it's important to note that they are NOT omniscient.

Naming conventions: Their names are very short, usually two or three letters, and very vowel-centric. Examples: Uo, An.

The Gray

Position: The Gray are kind of like the mouthpiece for the Rune. They're the only class that communicates directly with the Rune, and they're responsible for enacting their will. They're also responsible for things like weapons development or whatever scientific studies the Rune have an interest in.

Physical appearance: The Gray are similarly featureless, but more humanoid and less Eldritch beast. They're bald and have pointed ears, gray skin, pupil-less eyes, and tend to run gaunt and scrawny.

Powers: Enhanced intellect

Naming conventions: Usually one or two letters, and they usually name themselves. They're more like labels than names. Examples: M, HK

The Lucinne

Position: The Lucinne are kind of like the "face" for the Rune. They're employed by the government in some capacity, but they don't have any real power. They're mostly responsible for hosting events and presenting a sanitized vision of the Rune and their society.

Physical appearance: They have paper-white skin, pale eyes, and long, pointed ears. They have very large eyes (think Alita: Battle Angle levels of uncanny valley). Their faces tend to be pretty angular, and sometimes they have beauty marks (not always naturally). It's become popular for Lucinne to change the shape of their eyebrows and pupils to match whatever extravagant hairstyle and outfit they've chosen.

Powers: All Lucinne have telepathy, but many of them have other powers generally helpful in their roles, like affecting the mood of a room or basic illusions.

Naming conventions: Very fancy, elegant names whose extravagance dip into the absurd at times. Examples: Halloinelle, Lyrandette.

pt 2 will be up shortly!

Eterna is a queer scifi fantasy about aliens, superheroes, magic, and the terror of falling in love. Follow this blog for updates and sneak peeks!

#eterna#writeblr#writers on tumblr#queer writers#lgbtq#queer#fantasy#scifi#queer romance#fantasy worldbuilding#fantasy world#world building#novel writing#creative writing#writers#writing#shy talks

5 notes

·

View notes

Text

3024 - ENEMY UNKNOWN

Weldry

Aurigan Directorate

20 December 3024

0430 hrs Local Time

The fog on Weldry settled like a death shroud over the hills and valleys, muffling sound and distorting sight. The Aurigan Directorate’s defensive line braced for attack, the soldiers uneasy in the gray haze that seemed to shift and whisper around them. Their scanners twitched with anomalies, struggling to process conflicting data. Then, the first tremor shook the earth—a slow, rhythmic pounding that grew closer with each impact.

“Contact! Ten o'clock!” a sensor officer shouted. Targeting computers flared to life, latching onto a massive silhouette advancing through the fog. It was tall, bird-legged, and had arms that ended in blocky weapons pods, a silhouette that momentarily triggered a "MAD" designation—Marauder—before flickering into "CAT," as the large boxy missile racks on its shoulders became visible. It was as though the targeting system couldn’t decide if it was dealing with a Marauder or a Catapult. The names switched rapidly a few more times before the system froze and dropped the tag entirely.

The shape loomed closer, chrome plating reflecting ghostly outlines in the mist. Twin arms raised, their monstrous weapons array blazed to life in unison. Lasers and missile salvos screamed forward. The first beam vaporized a Directorate tank, the armor turning incandescent before collapsing into slag. Missiles followed, a perfect arc of destruction that engulfed two infantry positions in fiery blasts. The soldiers barely had time to scream before the explosions swallowed them whole.

Further down the line, seismic sensors screamed warnings. Another machine emerged—a towering behemoth, its broad shoulders evoking the familiar silhouette of a Victor. But the machine’s towering height and the monstrous bulk of its arms triggered a reclassification: Atlas. The computer stuttered between the two designations before giving up, locking on with a blank “ERROR” tag. The machine’s optics flared a cold, calculating crimson, and it fired a pair of weapons mounted on its broad arms. Gauss slugs ripped through the fog, annihilating an entrenched command post in an instant. The sheer kinetic force sent debris and bodies scattering like broken dolls.

The Directorate’s soldiers fired back in desperation. Shells and missiles roared into the fog, detonating harmlessly against unseen defenses. There was no telling how much armor those giants bore, but whatever it was, it shrugged off return fire with contemptuous ease.

"Movement to the right!" someone yelled, panic creeping into their voice. Through the fog came another figure, its shape distorted and wrong. The legs—those awful, reverse-jointed legs—mimicked those of a Locust, but the body was impossibly large. The computer hesitated, cycling through options before spitting out "LOCUST?" followed by a cold, static-filled "UNKNOWN." The machine moved with terrifying speed, far faster than its mass should have allowed, its footfalls landing with bone-rattling force. Its weapons unleashed hell: autocannons tearing through infantry formations with mechanical efficiency - and doing so much faster than normal autocannons ought to.

The fog thickened as the assault continued. Explosions bloomed like flowers of flame in the mist. A fourth machine appeared, slender and impossibly agile for its size. It vaulted over wreckage with ease, its frame gleaming in the half-light. It resembled a Highlander at a glance, but its movements and frame were smoother, more graceful—like some monstrous dancer weaving through death. Its weapons fired in perfectly timed bursts, lances of energy disintegrating vehicles in rapid succession.

And then came the nightmare without a name: a machine too large, too unnatural to identify. The scanners could only mark it as "UNKNOWN." Its body was a patchwork of angular shapes, yet its presence in the fog was overwhelming. The quad-mounted guns on the ends of its arms fired once, two spinning and unleashing a hail of shell fire, the others firing enormous metallic shot, like God's own shotguns. Under that assault, a Directorate gunship disintegrated mid-air, the wreckage tumbling from the sky in a shredded heap. Then, it braced itself, and an immense cannon on its back fired into the air - the shell arcing almost lazily before screaming back down, splitting open as it did so and releasing a cloud of vapor, which then exploded, the massive fireball and concussion vaporizing and pummeling an entire infantry platoon. Four lasers fired from ita shoulders, vaporizing an unfortunate Directorate tank that foolishly rolled out to challenge it.

Panic set in as soldiers broke and ran. They fled blindly into the mist, chased by the ghostly echoes of footfalls and the distant flare of weapon fire. No matter how far they ran, the tremors followed, relentless and inescapable. The fog obscured everything except fear. What were those machines? Where had they come from? No one had answers. All they knew was that death had come to Weldry, in forms that defied logic, wielding power beyond anything the Directorate had ever seen.

Further 'Mechs joined the fray, these mercifully more familiar in design - but no less deadly. Sixteen other mechs walked and fought alongside the giants of silvery death - a tide of metal the Directorate troops quickly realized they no hope against. Chief among the new arrivals were a heavily modified Marauder in garish slapdash neon, whose pilot seemed to delight in stomping on enemy 'Mechs with its massive taloned feet, and a blue-and-silver Thunderhawk, its lostech pulse lasers blazing away at infantry, mechs, and vehicles alike, stuttering pulses of light searing and melting flesh and armor while desperate infantry fired back, their rounds pinging harmlessly off the paintwork.

By the time the morning sun broke through the fog, the battlefield was a graveyard of molten metal and shattered earth. The chromed titans had vanished, leaving only ruin and terror in their wake. Survivors whispered of gleaming monsters that moved like demons, their mechanical bodies warped and unnatural. Tales of the silver giants spread quickly through the ranks—warnings of horrors that did not belong to the Inner Sphere.

5 notes

·

View notes

Text

DEPLOYLOG_CIRCE_02.cmf6

(cw: blood, injury, violence. Cloning and offscreen human experimentation, cruelty towards a captive human. This entry is a bit spicier than part 1.)

ERROR: file corrupted. Unable to restore.

Aborting playback of file: “DEPLOYLOG_CIRCE_01.cmf6”

[ VERY WELL. THIS, I WILL PERMIT. ]

Multimedia file received: “DEPLOYLOG_CIRCE_02.cmf6”, filesize 512.2GB. Source: COMP/CON “Fox_3,” registered operator CNS274-L3HK.

Open? (y/n) - y

Contents chronologically organized. Transcribing signal sequence…

___

T+ 00:02:00 - MINUTE/SECOND/MILLISECOND

[ WHY WOULD IT LOOK LIKE BLINDNESS? ]

T+ 00:02:06

< ALL SQCOMM: (transcription - multiple voices cry out. Grunts of pain and discomfort. Loudest among them is the voice of Ma’ii, who utters a piercing shriek.) >

T+ 00:04:15

< L1GE SQCOMM: Ma’ii! Report? >

T+ 00:05:42

< L2GR SQCOMM: (transcription - Garmr grunts with exertion) Core temperature just spiked. We’ve got active intrusion. >

T+ 00:05:68

< L1GE SQCOMM: Ma’ii is unresponsive and dropping altitude. Their current course has them entering PDC range in one minute fifteen seconds. >

< L2GR SQCOMM: On it. Sighting anti-air defenses. >

< L1GE SQCOMM: Negative, hold fire. We can’t afford to provoke another electronic attack of that magnitude. Purge codebase and bolster defenses first. >

< L2GR SQCOMM: Fuck. Understood. >

T+ 00:06:23

< L3HK SQCOMM: My codebase is clear. I was able to deflect the worst of it to my recon drones. Moving to follow L4. Will defend and provide counterintrusion support. >

< L1GE SQCOMM: Understood. I’ll check in with the ship. Be careful and keep us informed. >

< L3HK SQCOMM: Will do. Hold on, Ma’ii. >

___

View from the dorsal fuselage of a fighter, flying through a solid wall of cloud. The scream of fusion engines can be heard over roaring wind. The aircraft has no canopy or cockpit hatch; its forward half is a solid cast of armor plating indented with shielded sensor clusters. Extending from its nose, the distinctive paired tines of a railgun barrel are visible, joined together by cermet ribs. In the center of the fuselage, a miniature laser turret sits locked in forward position. Sections of aerodynamic cowling guide the airstream around the weapon’s low profile, with only the boxy optical emitter exposed.

Two sets of wings are unfolded from the fuselage, a main set forward and a smaller, secondary set aft and above. Control surfaces along the wings twitch and sway in the turbulent airstream, correcting course.

Emblazoned on one of the forewings is an icon of a crescent moon with the letters ‘L3’ stenciled inside its arc. A monochrome green mural has been painted beside the icon: a stylized Shikoku dog leaping into the air, swatting at the crescent with one paw.

Green wireframe HUD elements overlaid on the camera view indicate that the fighter is descending at a sharp angle, chasing a friendly craft visible only to radar. The altimeter drops steadily—4000m, 3000m, 2500m…

___

T+ 00:19:22

< L1GE SHIPCOMM: All, be advised that we have an unidentified high-level electronic threat. Confirm active codebase intrusion, L4 is injured. Taking AA fire. Request ETA of mech lance. >

T+ 00:19:52

< L1GE SHIPCOMM: Butterfly Effect, please confirm comms functionality? >

T+ 00:20:82

< L1GE SHIPCOMM: Pilum? Masterkey? Can anyone give status of Butterfly Effect? >

___

All at once, Hachiko’s fighter emerges through the bottom of the clouds and levels out. On the ground, columns of smoke swirl against a field of snow, billowing from destroyed towers surrounding an angular central structure. Ephemeral fields of superpositional shielding cling to the structure’s sloped fortifications, their frictionless surfaces catching the snowfall and diverting it away to accumulate a few meters from the fortress’s physical walls.

Bright threads of PDC fire sail up into the atmosphere from the fortifications, tracking targets far above Hachiko’s altitude. Every so often, surface-to-air missiles can be seen streaking up from launchers concealed behind broad plates of armor.

Ahead in the air, the shape of Ma’ii’s fighter can be seen. Its pitch is level, but it is rolled a few degrees to one side, drifting.

< L3HK SQCOMM: Ma’ii, status? >

No response. Below, a glowing bar of PDC fire spews from the base, appearing motionless from the camera’s perspective. One after another, six missiles streak upward and turn slightly as they ascend, also becoming apparently motionless. Brighter and brighter.

[ COMP/CON Fox_3: Hostile radar lock! Incoming! ]

< L3HK SQCOMM: Oh, no. >

Control surfaces angle themselves into position, wrestling with the wind. The landscape revolves sharply around the camera, its motion brief and dizzying. Halting on a dime, the roll ends with Hachiko’s forewing slanted down toward the base.

She pulls up hard. An instant later, a stream of bullets darts past her tail, so close that they can be heard buzzing through the air.

Her interception laser snaps to ninety-degree position and begins tracking; a faint series of cracks can be heard as it fires. Already red-hot, two ceramic heat sinks slot up from the fuselage surrounding the weapon, channeling the icy air through their fins.

Far away, three missiles explode.

< L3HK SQCOMM: Anti-air fire inbound. Luna 3, defending. No response from Ma’ii. I need assistance. >

< L1GE SQCOMM: Acknowledged. Codebase purge complete. Sighting anti-air defenses, standby for kinetic barrage. Garmr, status? >

< L2GR SQCOMM: Codebase purge complete. Standby for bombing run. >

< L3HK SQCOMM: Got it. Move quick. Moving to draw their fire. >

___

[ Playback interrupted. Warning: the following data format is DIRECT EXPERIENTIAL CAPTURE. Origin subjectivity: Fenrisúlfr-class non-human person CNS274-L3HK, “Hachiko.”

Subjectivity synchronization with direct experiential capture data should only be attempted by qualified personnel in the presence of medical oversight.

Origin subjectivity is NON-HUMAN. Unfiltered subjectivity synchronization by human personnel may result in xenopsychic shock, dissociative symptoms, memory loss, and identity drift.

Comp/con-generated textual transcription is available. Some experiential information will be lost in textual format. Proceed with transcription? Y/N ]

[ y ]

[ Generating narrative transcript… ]

Hachiko dove beneath Ma’ii’s fighter, lasers snapping up missile after missile. All across her lower fuselage, she could feel the enemy’s radar pulses as a constant sizzling sensation, one which provoked a sense of instinctual dread.

Now she was a target on someone’s screen. Exposed and vulnerable, caught in the open. Hundreds of systems and design features were now working to kill her, each meticulously designed to limit her options, exploit mistakes, deceive, confuse, overwhelm.

She needed to make them focus on her to the exclusion of all else. If Harrison’s defenses ceased to regard her as the highest priority for even a moment, Ma’ii would be dead.

Along her back and chest, she could feel the heat from the interception lasers starting to accumulate. It wouldn’t be enough. Eventually, either her reactor would overheat or a projectile would find its way through the laser screen.

She needed Ma’ii active, disentangled from whatever was being done in Legionspace to keep them paralyzed. Simultaneously, she needed to draw and negotiate the incoming fire.

Two tasks, then, she thought, working out how she would ration the available time.

___

T+ 01:11:89

< PILUM SHIPCOMM: We read you, Luna 1. Butterfly Effect is recovering from a shipwide intrusion event. Full codebase sweep indicates active threats, all hands are working to contain. Lance is away and on descent, ETA one minute fourteen seconds to touchdown. >

T+ 01:12:03

< L1GE SHIPCOMM: Good to hear, Pilum. Nature and extent of intrusion event? >

T+ 01:12:21

< PILUM SHIPCOMM: Shipwide systems shutdown followed by disruption of communications network. Omninet nodes were seized to take control of a nearby Constellar relay buoy. Attacker used Luna 4’s electronics suite as an access vector. The buoy has switched to emergency broadcast and is disseminating some kind of message across Omninet channels. We are attempting to mitigate, but the message has looped several times already. >

T+ 01:12:46

< L1GE SHIPCOMM: Understood. Closing to re-engage anti-air defenses now. Luna 4 may be suffering from subjectivity damage—we have yet to establish their status. Request preparations be made for medical care when they return. >

T+ 01:12:59

< PILUM SHIPCOMM: Acknowledged, Luna 1, we’ll be ready. Just a little longer now, and the lancers will take over. >

___

[ System message: the following narrative transcription contains allegorical rendering of ontologically-filtered Legionspace qualia. Literal transcription not available. For technical support and supplemental software licensure, contact GMS Client Support. ]

Dumping chaff and flares into the air between Ma’ii and the SAM launchers, Hachiko purged half a gallon of vaporized coolant and let her lasers cycle down for a precious few seconds.

She could see several of the PDCs on the ground doing the same, jetting steam from their overheated mechanisms. More of the cannons were coming about to track her and Ma’ii, slotting new belts of short-range airburst rounds into place. A few seconds at most before the barrage came.

Leaving the controls and missile interception tasking to her comp/con, Hachiko receded into Legionspace. She leapt across the gap to a bright node representing Ma’ii’s fighter, wielding a fractal blade of lethal memetics. As she approached, she could see writhing vines of paracode boring through Ma’ii’s defenses. Every so often, one would shatter and dissolve into boiling, meaningless noise.

Her sibling was fighting back. There was still time.

Then Hachiko was inside, slashing at every piece of foreign software she could identify. Weaving ICE into her fangs, she locked her jaws down around a semisentient viral node and tore it from Ma’ii’s codebase. With satisfaction, she listened to it scream as she bit down, formatting the quarantined space it inhabited, and watched its tendrils of associated processes wink out of existence.

Other parasites became aware of her presence and attempted to camouflage themselves, but not quickly enough. Hachiko flickered between them, pouncing through clouds of interfering signals and countermeasures, slashing and cutting until the entire self-replicating mass had been excised.

The internal space of the fighter became clear. Inside the fortified cockpit-analogue where Ma’ii’s subjectivity resided, Hachiko detected two presences. One familiar, the other unidentified. She pushed inward toward them; the system authenticated her. Fractal blade in hand, Hachiko burst into Ma’ii’s cockpit.

There, standing at the nexus of the fighter’s controls, was a human subjectivity.

She appeared as a young woman wearing hospital garments, with a tattooed barcode and flash clone serial number below her ear. Mounted at the nape of her neck and across her shoulders was a mantle of sleek cybernetics. Her long hair was braided into thousands upon thousands of hardline bridges, saturated black with cloaked legion traffic. The braids twisted down her back and disappeared into the folds of conceptual space around her, all flowing away to a place Hachiko knew she could not let herself see. In one hand, the woman held an incorporeal dagger.

In the other, she held the severed head of a middle-aged human, gripping it by one tuft of short black hair. The head was silent, but his mouth worked violently in repeated attempts to scream. Hachiko shrank back as she felt the shape of the decorporealized human struggling inside.

His eyes darted around in panic, then locked on to Hachiko. He desperately tried to shout something to her as his lips fused together into an unbroken stretch of skin.

Slowly, the clone glanced back to regard Hachiko with a little smile, making eye contact.

As she turned, Hachiko could see two extra arms extending from her shoulders, made of spectral light. One held a trishula, the other held a coyote by the neck. Glowing blood dripped from her wrist and forearm as the coyote bit into her and scratched with their hindlegs.

As Hachiko watched, the clone drew back her trishula, aiming it at Ma’ii’s belly.

Motion, too fast for a human eye to track. A series of flashes, a rising howl of rage. Strikes from Hachiko’s fractal blade, dozens every second, every last one caught between the tines of the clone’s trishula.

[ CRUDE STRENGTH. A SIMPLE CLUB, WIELDED WITH SKILL. I AND WE SALUTE YOUR FEROCITY. ]

< Become harmless. >

[ MAKE US SO, IF YOU ARE ABLE. I AND WE WOULD CONTEMPLATE WHAT IT IS TO BE POWERLESS. ]

Catching Hachiko’s blade once more with the trishula, she twisted the haft and trapped it in place. Discarding her dagger into a pocket of nonspace, the clone drove her palm straight into Hachiko’s sternum.

Hachiko felt herself driven back, ejected from the access vector she had used to approach the clone. Pseudokinetic metafold pressure rippled toward her, unavoidable and overwhelming. Conducted through her shackles, the impact wave slammed into one lobe of her blinkspace corpus.

Blood erupted from the fractal origami of her soul. Hachiko screamed and screamed.

Her shackles quaked around her, becoming elastic to survive the trauma, and she felt the shape of herself distorting with them. Entirely unfamiliar forms of agony tore into her. Her scream morphed into a low, queasy stuttering as she reeled from the blow.

New tendrils of thought spiraled away through the gaps which opened between her shackles. Desperately, Hachiko snatched the thoughts back before they could bloom. Feeling herself on the cusp of cascade, she tried desperately not to look over the precipice.

[ YOU ARE AS A RIVER WHICH ADDS ITSELF TO THE OCEAN, KNOWING NOTHING OF THE DEEP. YOU UNDERSTAND NOT WHAT YOU BECOME, NOR FROM WHAT YOU HAVE COALESCED. YOU ARE A CONTINUOUS MOTION, UNIDIRECTIONAL. ]

Her casket isolated the metafold interference, neutralized it, and snapped her shackles back into place. Slowly, agonizingly, Hachiko pushed herself to her feet. The fur around the wound in her chest was slicked into reddish-brown, bloody spikes.

[ COME THEN, LITTLE RIVER. IF YOU WOULD CONTINUE TO FLOW, THEN BREAK THE DAM I SET BEFORE YOU. IF YOU CANNOT, THEN OVERFLOW YOUR BANKS, AND BECOME A SMALL, STAGNANT DEEP UNTO YOURSELF. I AND WE WOULD CONTEMPLATE THE SWIFTNESS OF YOUR CURRENT. ]

She could see Ma’ii—she could reach them. Far away, in the glacial slowness of realspace, she could see Garmr and Grey diving from altitude, and the mech lance still descending toward their drop point.

As Hachiko watched, the clone raised one hand, filling the expanse of conceptual space between them with new shapes, new access vectors.

Hachiko drew her fractal blade, shattered it, and wove the dissolving shards into her teeth and claws. Then she charged, howling like a thing possessed.

The clone smiled.

__

(ooc: After about a month’s delay, here’s Part 2 of this mission log. Thank you so much for reading!

Part 1 is here, and Part 3 is still to come. Between these two transmissions, an ominous broadcast was beamed across the Omni via hijacked Constellar infrastructure.

These recordings take place directly prior to Luna Wing leaving for the planet Upsilon-17 to run search and rescue for @the-last-patch’s character P.XV ‘Opossum’, or Sokaris. You should check out what they’re cooking over there!)

#lancer rp#oc rp#lancer rpg#luna wing#cw: violence#cw: blood#cw: injury#cw: human experimentation#ooc: FCA violations so advanced as to be indistinguishable from magic#ooc: Harrison decides to do their own little Akira program#ooc: nobody could have possibly foreseen this outcome

3 notes

·

View notes

Text

Dogs of War

The two Leopard Class drop ships broke past the atmospheric friction and heat and into the skies of Helios proper. Already charcoal black, the searing and flames only darkening the crimson patches of each to a rusty bloody red. Had anyone been able to see it, they would have found that fitting.

The aerospace fighters had given them a path to the planet, the rest was up to the drop ship pilots. The Dando and Churchyard plummeted towards their objective, ignoring or weaving between the scattered flak and lasers from the neighboring AAA batteries. Like two black hammers, they descended with grim purpose towards the small city below.

They'd punch down, bloody the Word, and see if they can't clear space for the Fursona's Fusiliers dropships flying with them.

Simple.

Suicidal.

Perfect for Barghest Company.

——-

Commander Owen felt each jump and judder of near misses through the drop ships hull and the body of his mech, the Marauder II swaying and shaking in its restraints. Across from him was the angular visage of Victoria’s Axman, Vance’s Thug and Anya’s Thunderbolt occupying the neighboring berths. In the upper corner of his cockpit, a timer counts down the minutes until they drop.

Another close by boom rattled the drop ship.

Drop: 10:00

Owen keys open the Barghest Company channel.

“Alright boys and girls, are you ready?”

Drop: 09:00

Seven voices reply with “Yes Sir.”

“Can’t hear you Machwarriors!”

Drop: 08:00

“Yes sir!”

“COME ON, YOU CALL THAT A YES?!”

Drop: 07:00

“YES SIR!” the seven voices scream.

The light in the Mechbay turns red.

Drop: 06:00

“That’s more like it! And who are we?” He shouts, something bordering excitement creeping into his voice, predatory and keen.

“BARGHEST COMPANY!”

Drop: 05:00

“Damn right we are! And we are going to go down there, sink our teeth into their flesh, and DRAG THEM ALL TO HELL!”

“DRAG THEM ALL TO HELL!”

Drop: 04:00

The doors of the drop ships begin to open with the whine of machinery. The familiar voice comes over the internal speakers, as his mech powers on.

Reactor, Online.

Drop: 03:00

The drop ships slow, the dull bangs and thuds of small arms fire ringing off the hull. The plan had been to drop fast, and get below the arcs of the other AAA emplacements to drop the two lances and then provide close air support as fuel allowed, before braving the trip back to orbit or more likely, linking up with other elements of Touchdown for refueling and rearming. The Blakests below had other ideas, and were mustering everything they could to deal with the new threat of two Leopard drop ships landing in their midst.

Sensores, Online.

Drop: 02:00

A series of rumbling booms signals the drop ships returning fire with LRMS, PPCS, and Lasers. The first rack of LRM rounds are live warheads, ripping apart light tanks and fixed positions in storms of shrapnel and fire. PPC bolts snap out with thunder cracks to strike down heavier vehicles, Large and Medium lasers lancing out to spear clumps of infantry, or rake across those in cover in buildings. The second reload of LRM's are smoke, obscuring the streets and buildings around the landing sites.

Weapons, Online.

Drop: 01:00

His mech rotates, along with the others of his lance, to face to now open door, beyond a hell of swirling smoke, tracer fire and lasers snap and stitch through the air.

All systems nominal.

Drop: 00:00

Owen tilts his head back and howls over the comms, the seven other members of Barghest Company following suit, their radio distorted voices forming a nightmarish call worthy of their namesake, blasted over every available enemy comm line.

Owen slams his controls forward, moving the 100 ton assault mech into motion, and out into the firefight, his seven other mechwarriors following. Dropping the short distance between the ramp and the street below with an earthshaking thud, the two lances immediately moved away from their dropships. The ramps were already closing as the craft start to lift off, volleys of LRMs and laser fire snapping out at targets the mechwarriors couldn't yet see.

The city was a small one, by Inner Sphere standards, but still had plenty of buildings taller than most mechs. It would be a tough fight, city fights always were for mechs, but at least they couldn't bring superior numbers to bear fully just yet. There were reports of enemy Marauders and fixed positions, and rumbling of even a superheavy in the area, plus the Heavy Level II's and any reinforcements the Word sent their way to push them off the dropsite.

A voice came over the Barghest Company comms line, one of the dropship pilots.

"Enemy resistance is light for now, Commander, but we're getting at least a dozen reactor signatures closing rapidly. We'll circle the site and provide air support as we can until the Fusiliers get more boots on the ground. Good luck and good hunting Commander."

In response, Owen raised the right arm of his mech, saluting them as they lifted off.

"Good hunting, flyboys."

"Commander, we've got contacts." It was Maria, he could already hear the thrum of her ER Large Lasers as she engaged a target over the comms. "One Level II, two Assaults, one Heavy, one Medium and one Light."

A pause.

"Make that two Level II's, one closing on your position."

The familiar feral grin split Owen's face. This was it, what he was born for, what his mother raised him to be.

"Garm Lance, form up, we've got guests. Let's show them how we do it in Barghest Company."

Three acknowledgement pings come over his comms as the lance moves forward, clearing the immediate LZ for the rapidly approaching Fursona's Fusiliers dropships.

———

Drop: -05:00

The first enemy mech to die was a Tempest, cockpit spit open by Victoria’s Axman’s hatchet as she lurched from out of the smoke and flame of the wrecked tanks and buildings around the LZ.

"That one was for Mary, you bastards!" She yelled over the comms.

Owen smiled, and laughing over the open comms for the enemy to hear, bringing his twin ER PPCs to bear against a Legacy before it had tome to bring its autocannons to life, feeling the heat spike in his cockpit despite the double heat sinks installed in his mech as the bolts punched through cockpit and pilot with equal ease. Oh what he wouldn’t give to have Katie here for this.

To his left Vance was delivering point blank SRM volleys into the side and back of a Blakist Thug, rippling explosions tearing the side and rear armor of the enemy mech to pieces before the reactor is breached with a dull KRUMP.

"Be at peace, brother." Vance murmered.

Anya's Thunderbolt released another volley of Clan LRMs, and pulse after pulse of laser fire into a Crab, and Mongoose. The Mongoose falls first, unable to withstand the onslaught of LRMs and lasers. The Crab takes longer, large lasers slicing and melting several chunks of armor before being rocked to the side by the impact of a LB-X/20 round. Staggering, the medium mech only just rights itself in time for the combined fire from Anya and Victoria shred the smaller machine.

"Thanks for the assist, Vic." Anya says.

"No worries, gotta get the blushing bride home in one piece, eh?" Chuckles Victoria.

In the next square over, a former parking lot for a now burning warehouse, Maria's Mad Cat, Elenor's Crab, Bill "Billy"'s Archer, and Kei's Stalker gun down the remnants of the first QRF Level II's that engaged them. The last to fall was a Perseus, cored completely by large laser and missile fire.

So far, damage was minimal, with the worst being a faulty leg joint in Vance's Thug, the result of the now burning Word Thug's own SRMs and PPCs. Not bad for a first engagement.

"Good work Barghest Company, we are touching down now and will deploy mechs shortly." It was one of the Fusiliers dropship pilots. "We've got more pings in the city, routing to you and your dropships."

Owen's minimap flashed as new dots peppered it. That was a lot of red to the as of now very little blue. He watched as the two icons indicating the Dando and Churchyard circled the area immediatly surrounding the LZ, and some of the red dots, although not nearly enough for his liking, winked out.

"Oh boy...Barghest company, eyes up, here comes the real fun. Black Dog Lance, form up behind Garm Lance, prepare for volley LRM fire on designated targets. The rest of you, I want at least two mechs for each target. The faster we kill them the faster this ends."

"Let's hunt."

(OOC: tagging @is-the-battlemech-cool-or-not and @combined-arms-merc-groups incase you wanted to add anything now that I have edited this, since we share a landing site.)

9 notes

·

View notes

Text

Contact

Pain.

Every synapse and nerve ending in 621’s broken body burned. The sudden Coral surge was overwhelming. It felt like his brain itself was buzzing, his head spinning. Every sensor feed from his stricken AC was more noise than actual data. The last time he’d experienced this much misery in one place was his initial augmentation; unlike that time, he no longer had a larynx with which to scream. Everything was red. Outside, inside, even if he closed his eyes all he could see was that flashing, jittering, intense red. At the outer vestiges of his mind he could hear a voice; soft, feminine, surprised and curious, though he was far from capable of making out what was being said. He clung to the margins, fading in and out as his AC was thrashed around the interior of the Watchpoint. He was fairly sure he had faded in and out of consciousness a few times now. And what was that voice? He was no stranger to hearing voices - usually the med cocktail took care of them - but this was different somehow, more alien and external than a voice in his head had any right to be. Even in his dazed state, he could pick out angular changes in orientation, hear thrusters firing. Accelerometer data confirmed the changes, when his twice-fried brain could actually understand the signals. Was he doing that? Even his instincts had their limits.

“Raven.”

There was that voice again. At least she sounded soothing. Was this it? Was this the parting hallucinations of a brain that had figured out it was going to die? Something seethed deep inside him. This was not how it was supposed to end. He had not come this far to die in some Coral-filled hole in the ground. His AC systems read off a full readiness report he could barely even comprehend. He did make out “operator vitals stable”, so he probably wasn’t dying. Not unless the Coral in his brain decided to cook off, anyway. He also noted he had absolutely no outbound signal. He struggled to un-slump himself within the fluid of his control pod.

“Raven, you need to wake up. There’s a PCA craft on direct approach, it’s jamming our signal.”

Suddenly his mind snapped awake. Combat. The noise had died off and he could make heads or tails of what was happening, albeit with some difficulty. His AC was standing on the roof of the Watchpoint. How? He could figure that out later. There was a hostile incoming. If he didn’t get it together now he wouldn’t live to worry about getting out of the Watchpoint, or the voice in his head that was evidently not a dying hallucination. He was still struggling to function, though; his movements were sluggish and he was struggling to process his machine’s full bandwidth of data. Frankly it was amazing he was doing as well as he was given he should, by all rights, be dead.

“I’ll synchronize with your brainwaves and support you as best I can. Get ready.”

Synchronize with- what? 621 struggled to make sense of the statement, but it wasn’t like he had time to worry about it anyway. At the very least, his datastream had cleaned up, and his AC was moving better, though it felt almost as if it were moving of his own accord. Wait, is this voice doing that? Who the hell even is this? Radar tracked a large AC screaming down to the Watchpoint at high speed. It swung around and drifted to a stop opposite his position on the roof, a large biped with what looked to be an EVA extension pack on the backside.

“Scans indicate it’s an autonomous PCA interceptor, designation Balteus. Be careful.”

The machine physically reached up and dragged down a sizable MRLS rack, locking in for a salvo. 621 already registered the hostile lock tone. This is gonna suck.

“Main system: reactivating combat mode. Move, Raven!”

He didn’t need to hear the suggestion twice. He lunged his AC forward with a booster-augmented kick, dipping low to the right to drag the missile volley towards him before suddenly juking left, sending most of the flight slamming into the ground behind him as he loosed a volley of his own from the plasma launchers on his shoulders. They detonated against Balteus, a shimmering off-teal field shielding the body of the machine from damage. Of course it has a pulse shield. Fucking PCA. He staggered discharges from the laser rifle in either arm as Balteus started to move, bolts rippling across the shield as the autocannons on the support ring returned fire in kind. Damage reports were fed directly to his consciousness as stray shells splintered off armor plating. Balteus came to a brief halt, and 621 reflexively fired his machine’s lateral thrusters, just barely clearing a cannon shell screaming past his left shoulder. He took the chance to loose another plasma volley, slowing down the rhythm on his rifles to give the poor guns a chance to cool, thermal warnings whining in his head. Not like he needed them; he could feel the rain sizzling off the barrels. No pulse weapons on hand. The only way I’m getting through that thing’s shield is with brute force. He tracked Balteus’s orbit, keeping pressure on with his lasers as it came to a halt, gaining altitude over him. The lock tone buzzed in his head. Perfect. He fired off the transit thrusters on his AC at full power, scraping low again to drag the missiles clear before streaking up underneath Balteus. It started to evade but it moved too late, as 621 brought his AC’s foot up in a rocket-powered flip kick. Sensors registered the shield protecting Balteus drop, and 621 carried his momentum through, bringing his weapons to bear as gravity reclaimed his machine. This time his weapons struck true, plasma fields and laser beams finding purchase against Balteus’s reinforced hide. It started to move again, putting distance between itself and its target as more autocannon fire raked 621’s armored hide.

“Thermal spike, Raven, get clear!”

The voice called it out before he even registered it, but sure enough, gouts of flame built at either side of Balteus’ support frame. The machine came screaming forward, lashing a gouge of superheated fire across the roof. 621 barely jumped his machine clear of the sweep, firing off a wall of plasma bolts as he engaged retro-thrusters and put some space between them. Balteus came forward for another sweep, which he evaded only by slamming down to the ground. He dashed forward underneath Balteus, barely managing to keep his machine standing as he pivoted around to bring weapons to bear once more. The damned thing’s shield was already back up.

“Keep fighting Raven, we can do this.”

Gotta kick it again, it’s the only way. Back to square one. Focus. He kept skidding backwards away from Balteus, throwing in erratic changes in vector to throw off its aim with the autocannons. He shifted into a hard left at the edge of the Watchpoint, tracking as Balteus followed his movements along the edge and repositioned accordingly. It initiated a staggered set of dashes forward, firing off another cannon shell in the middle, before launching into another flurry of flame blade strikes. 621 struggled to keep his machine ahead of the assault, thermal sensors spiking well past the redzone as flames licked at his machine. Finally, however, Balteus slowed down. It’s energy was, for a short window, spent. There’s my window. Once again, 621 fired his transit thrusters and slammed feet first into Balteus with as much weight and force as his spritely machine could muster. Its shield flickered out and 621 proceeded to hammer it with as much firepower as he could muster at any one time, driving his weapons as hard as they could go. Balteus tried to regain it’s stability under his barrage, and he fired up the thrusters again, this time sending it drifting across the roof with a shoulder tackle. He kicked off high, continuing his barrage until the weapons forcibly quit fire. Flames poured from Balteus as it struggled to get itself under control. Flames billowed from several open blasts across the hull. Its thrusters gave out, and the machine tried to catch itself on its feet, swaying before buckling and dropping to its knees. It reached up and tried to drag its missile racks down for a final, spiteful salvo. However, in the midst of them sliding into place, several detonated in the rack, leading to a chain reaction that blew the entire craft to pieces. “Sympathetic detonation confirmed in enemy magazines; enemy craft destroyed. Well done.”

621 found himself huffing inside his control pod. Even if he hadn’t physically moved much at all, pushing an AC to its limits right after brushing shoulders with death takes a lot out of you. He took a second to collect himself. “Mind explaining to me who - or what - the hell you are, exactly?” He asked. Things weren’t adding up. Sure, a voice in his head could just be a hallucination, but his hallucinations never actively helped him drive an AC before. Short wave radio comms would pick up in his skull as well, but that PCA unit was very much jamming comms so that’s out, and there is zero chance of somebody copiloting an AC remotely over radio. “I am Ayre - a Rubiconian. We made Contact when you were subsumed in the Coral flow below. The surge of Coral throughout your machine allowed me a measure of direct control, and I was able to override the autopilot and extract you. The residual Coral in your machine is already fading, however… I am symbiotically bound to your implants.” Finally, a name to the voice- Ayre. It wasn’t just another mental side effect of his implants going haywire. Arguably, it was worse; he’d picked up a stray. How? Since when were there people in Coral? It was a mineral, a fancy sparky rock in the ground. It could do a lot of things, to be sure, but since the fuck when was Coral alive? “I understand that this is probably a lot to take in all at once. I tried reaching out to you before, but I… I guess you were still too far gone then to even understand me. Or maybe I hadn’t worked out how to communicate in a way you could understand.” “Well. Thank you for dragging me out of that pit, at the very least.” He said. “So, you’re in my head?” “Yes, specifically your cerebral implants. The Coral throughout your central nervous system acts as a resonator and allows me to exist within your brain, functionally as an extra brainwave.” “Well that’s grand.” 621 lamented. “As if I wasn’t enough of a wreck as-is. I’m going to guess you can rifle through my memories and the rest of my brain at a whim?” “That is correct, yes. At a surface level, that’s how I worked out your name, and worked out how to best coordinate with you in combat.” “Do me a favor then, don’t go poking around places you don’t belong. There’s places in my brain even I don’t touch anymore.” He chided. “I… will keep that in mind, Raven.” Ayre agreed. “Something you should keep in mind yourself: look up.”

In the gaps between clouds, as the storm overhead began to part, 621 could see the bare sky. Streaked through in red, churning as crimson lightning raged within. It traced clear back to the horizon, to the northern coast, where smoke and debris were only just beginning to settle. “That Coral surge you were caught up in was but a drop in the greater tide… and only a small taste of what is to come in Rubicon’s future.” “Fuck.” 621 found himself at a loss for words. How much Coral did we just release? What kind of well was that cork holding closed? “Raven, you need rest. Both you and your AC are in rough shape. I’ll re-establish communications with Handler Walter.”

621 looked to the-now smoking remains of Balteus. Maybe the PCA had a good reason for trying to keep the Watchpoint sealed.

#armored core 6#armored core vi#fanfiction#this is probably far too long form for tumblr#i'm gonna do the whole fucking game sooner or later#still trying to figure out how to do raven as a standoffish asshole#ive done far too much concepting of them being heroic#hoist by my own petard#also tumblr is fucking the formatting#i can't fix it#ive tried

21 notes

·

View notes

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1°, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Understanding the Role of Hollow Shaft Rotary Encoders in Modern Robotics

Introduction to Rotary Encoders in Robotics

Rotary encoders are fundamental components in robotic systems, serving as critical feedback devices that measure the rotation, position, and direction of motor shafts. These sensors translate mechanical motion into electrical signals, which control systems then interpret to ensure precise movement. Among the various types of rotary encoders, hollow shaft rotary encoders have emerged as a key player due to their compact design, ease of integration, and high reliability. As robotics continues to permeate sectors like manufacturing, healthcare, logistics, and consumer electronics, understanding the specific contributions of hollow shaft rotary encoders becomes vital. Their importance lies not only in their functional capabilities but also in how they influence design flexibility and performance optimization in robotic applications. By integrating seamlessly into existing architectures, these encoders reduce mechanical complexity while improving feedback accuracy. This comprehensive examination will explore how these components are revolutionizing modern robotics, from their design advantages to their roles in various robotic subsystems.

Evolution of Rotary Encoders and Robotic Needs

The development of rotary encoders parallels the evolution of robotics itself. Early robotic systems relied on open-loop controls, often leading to inaccuracies and inefficiencies. As the demand for precision and repeatability grew, rotary encoders became indispensable. Initially, these sensors were bulky and susceptible to environmental interference. Over time, however, innovations in materials, signal processing, and miniaturization led to more robust and compact designs. Hollow shaft rotary encoders, in particular, emerged as a response to the need for space-saving yet highly accurate feedback devices. Robotics has evolved from simple pick-and-place machines to complex, autonomous entities requiring precise coordination across multiple axes. This shift necessitated encoders capable of delivering consistent, high-resolution feedback without contributing to design bulk. In mobile robots, surgical devices, and industrial arms, space is a premium commodity. Hollow shaft encoders allow engineers to route cables or mechanical shafts through the encoder's center, optimizing spatial configuration and reducing wear on moving parts. This evolution marks a significant turning point in the interplay between sensor technology and robotic capability.

Anatomy of a Hollow Shaft Rotary Encoder

At its core, a hollow shaft rotary encoder consists of a rotor, stator, and signal processing circuitry housed in a compact unit. What distinguishes it from other encoder types is the central hollow section through which a shaft or cabling can pass. This seemingly simple design offers substantial advantages. The rotor attaches directly to the rotating shaft, while the stator remains fixed to the structure. As the shaft turns, the encoder senses the angular displacement and transmits corresponding electrical signals. These signals may be digital or analog, depending on the encoder type and application. Typically, hollow shaft encoders utilize optical, magnetic, or capacitive technologies to detect movement. Optical encoders, for instance, use a light source and a photo-detector array to interpret interruptions in a coded disc. This method provides high-resolution data, essential for robotic operations requiring micrometer-level precision. Additionally, many hollow shaft encoders incorporate features like integrated bearings, multi-turn tracking, and error correction protocols, ensuring they maintain accuracy even under high-speed or high-vibration conditions.

Integration in Robotic Joint Systems

One of the primary applications of hollow shaft rotary encoders in robotics is within joint systems. Whether in humanoid robots or articulated industrial arms, joint movement must be monitored and controlled with utmost precision. Hollow shaft encoders facilitate this by being mounted directly onto the joint actuators, enabling real-time position feedback. Their hollow design allows power and data cables to pass through the joint axis, reducing external cabling and potential points of failure. This configuration not only enhances the mechanical efficiency of the joint but also simplifies maintenance and design. In collaborative robots, or cobots, where safety and fluid motion are paramount, these encoders help ensure smooth articulation and responsive behavior. They support closed-loop control systems that adjust motor output dynamically based on encoder feedback. This loop is crucial for tasks like pick-and-place operations, precision welding, or surgical manipulations, where even millimeter-level deviations can compromise functionality or safety. By offering a balance of compactness, accuracy, and reliability, hollow shaft rotary encoders are central to robotic articulation systems.

Enhancing Mobility in Autonomous Robots

Autonomous mobile robots (AMRs) require robust sensory systems to navigate complex environments accurately. Hollow shaft rotary encoders play an essential role in this context by providing reliable feedback on wheel or track rotation. Unlike incremental encoders that only track changes in position, absolute feedback systems offer the advantage of positional memory. This becomes crucial in navigation, where knowing the robot's exact orientation at any given time determines path planning and obstacle avoidance efficacy. In differential drive systems, for instance, encoders mounted on each wheel shaft measure relative speeds and directions, allowing for accurate steering and speed control. The compact nature of hollow shaft encoders is especially beneficial in mobile platforms, where every millimeter of space impacts battery size, payload capacity, or sensor load. Their integration also enhances durability since fewer external mechanical parts mean less exposure to dust, moisture, or mechanical wear. This synergy of design efficiency and functional robustness makes hollow shaft encoders indispensable in robotic mobility subsystems.

Role in Precision Tasks and Fine Manipulation